The products are characterized by small wear, high precision control and uniform particle size distribution. It can be widely used in micron scale experiment and production of superhard materials such as synthetic diamond and boron nitride.

Product Size: D50:1-25μm

Production Capacity: 2~7500kg/h

Feed Size: < 3mm

Material Handling: Artificial diamond, cubic boron nitride and other superhard materials.,etc

Reading Volume:

marketing@alpapowder.com

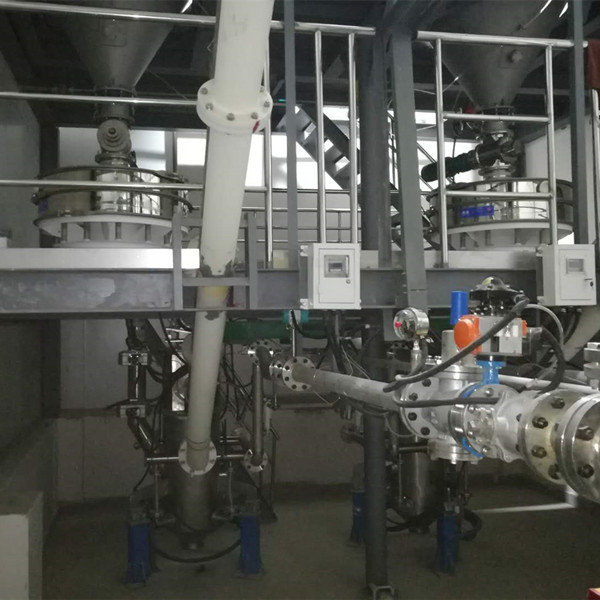

Shandong ALPA is a special equipment for Diamond Special Fluidised Bed Opposed Jet Mill, which is mainly composed of MQW series mill. According to the different superhard materials such as synthetic diamond and boron nitride, the production capacity requirements and applications are different, and the customized production is required.

1. Diamond special airflow grinder, materials collide with each other to crush, wear small, no iron pollution products.

2. Diamond powder with better particle size distribution can be obtained by one-step production without water, washing and dry process.

3. Stable and complete flow field and special sealing measures can reliably prevent the leakage of coarse particles with narrow particle size distribution and no large particles.

4. It has a certain shaping function for particle morphology.

5. The pneumatic crushing classifier has a variable combination structure: one machine can be used for both crushing and separate classification.

6. Easy to wear parts are wear-resistant treatment, greatly reducing the wear of the equipment, extending the service life. Automatic control, low noise, no dust pollution.

Fluidized bed jet mill works with feeding device, cyclone, bag filter and suction fan to form a complete grinding line. Compressed air flow after filtration and drying would go into milling chamber from nozzles and meet in the center area, where material would be impacted, milled and sheared.

| Parameters/specifications | MQW03 | MQW06 | MQW10 | MQW20 | MQW40 | MQW60 | MQW120 |

| Feed Size(mm) | <3 | <3 | <3 | <3 | <3 | <3 | <3 |

| Product Size(d97:μm) | 2~45 | 2~45 | 2~45 | 2~45 | 2~45 | 2~45 | 2~45 |

| Production Capacity(kg/h) | 2~30 | 30~200 | 50~500 | 100~1000 | 200~2500 | 500~3500 | 800~7500 |

| Air consumption(m3/min) | 3 | 6 | 10 | 20 | 40 | 60 | 120 |

| Air Pressure(Mpa) | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 |

| Installed Power(kW) | 21 | 42 | 85 | 147 | 282 | 415 | 800 |

Note:The production capacity is closely related to the particle size, specific gravity, hardness, moisture and other indicators of the raw materials. The above is only for selection reference.